Industry Success

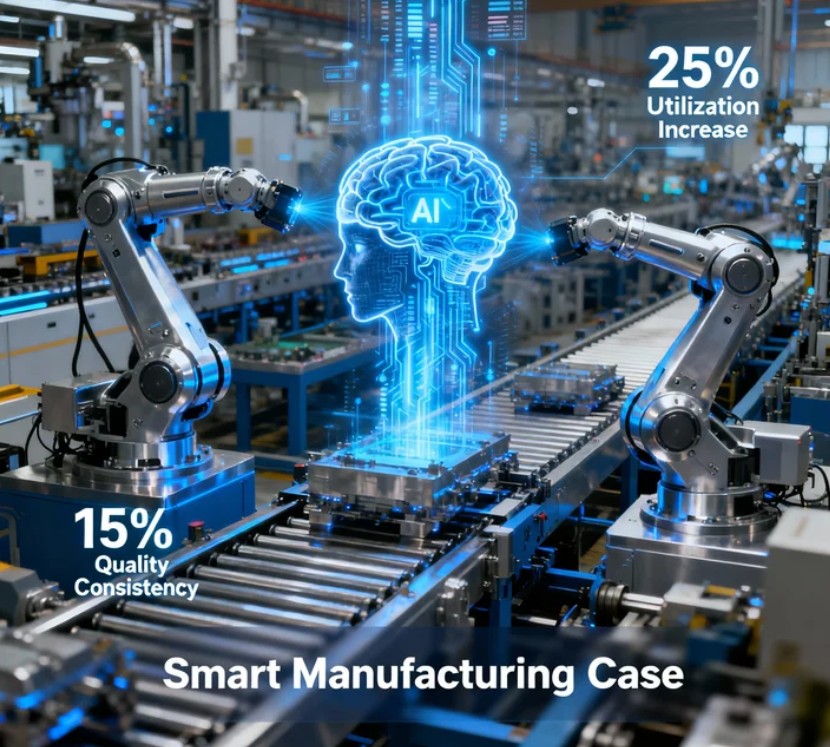

Smart Factory: 25% Utilization Boost

An end-to-end solution connects machines, collects data, and applies AI analytics. An industrial IoT platform gathers CNC, robot, and sensor data in real time to optimize process parameters and scheduling. One auto-parts project raised equipment utilization by 25%, quality consistency by 15%, and cut energy by 8%. Multi-brand connectivity and drag-and-drop visual analytics let process engineers extract value without coding, shortening pilot-run cycles.

Predictive Maintenance: 40% Less Downtime

Fusing vibration, temperature, and current data, the system warns seven to thirty days ahead, reducing unplanned downtime by 40% and maintenance cost by 30%. Transfer learning adapts to new equipment in three hours. Vision-based quality inspection identifies 200 parts per minute at 99.9% accuracy, supports few-shot model changeover, and cuts die-switch time from two days to two hours, enabling flexible zero-defect manufacturing.

Medical Imaging: <2% False Positives

The imaging platform analyzes CT, MRI, and X-ray modalities, achieving 98.2% sensitivity and 2% false-positive rate in lung-nodule detection and Dice 0.92 in brain-tumor segmentation, significantly accelerating radiology workflows. The drug-discovery platform employs graph neural nets and generative AI to shorten early compound screening from three-to-five years to under one year and designs novel targeted molecules, already deployed in top-tier hospitals and pharma companies, freeing clinicians and researchers for innovation.